21/01/26

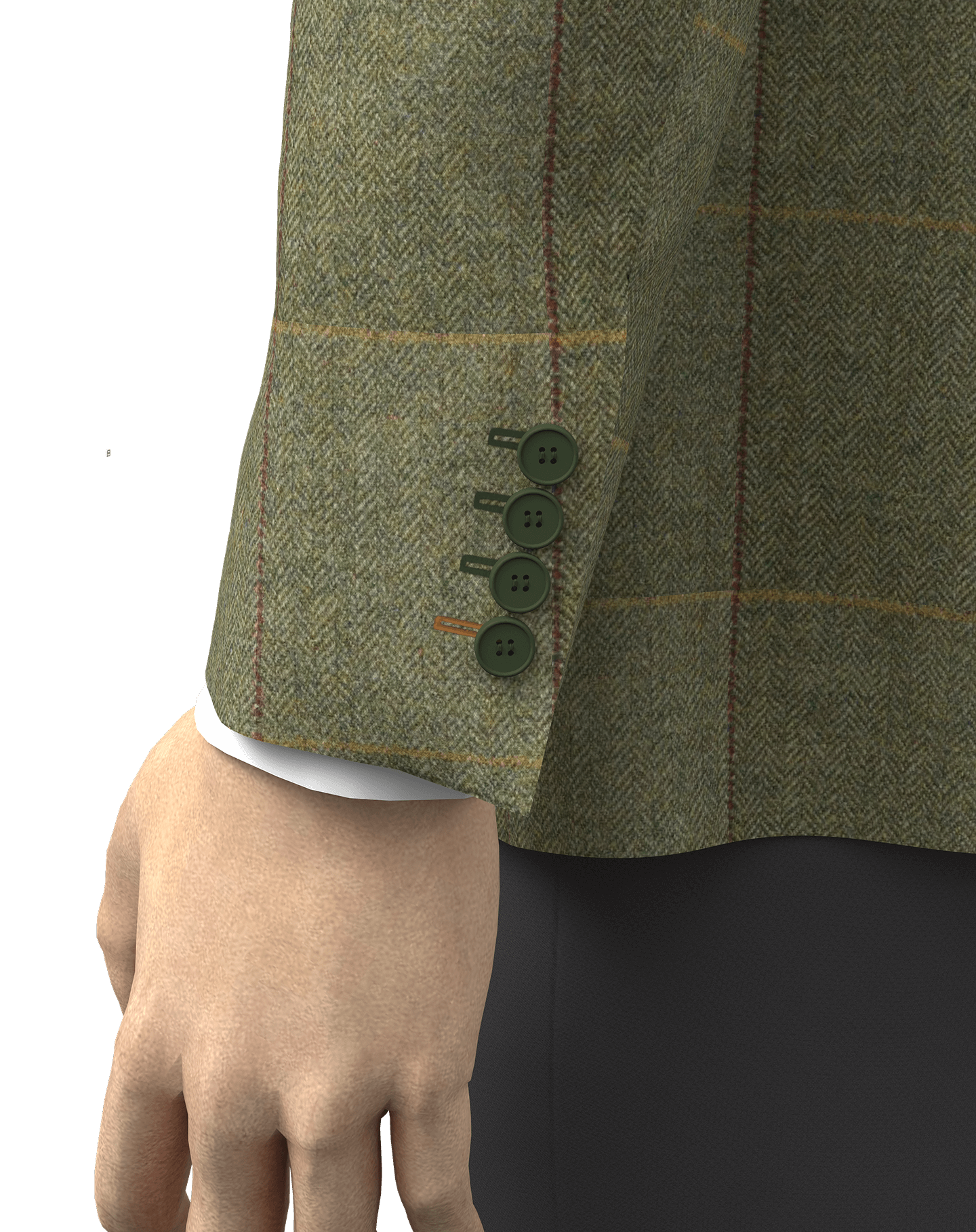

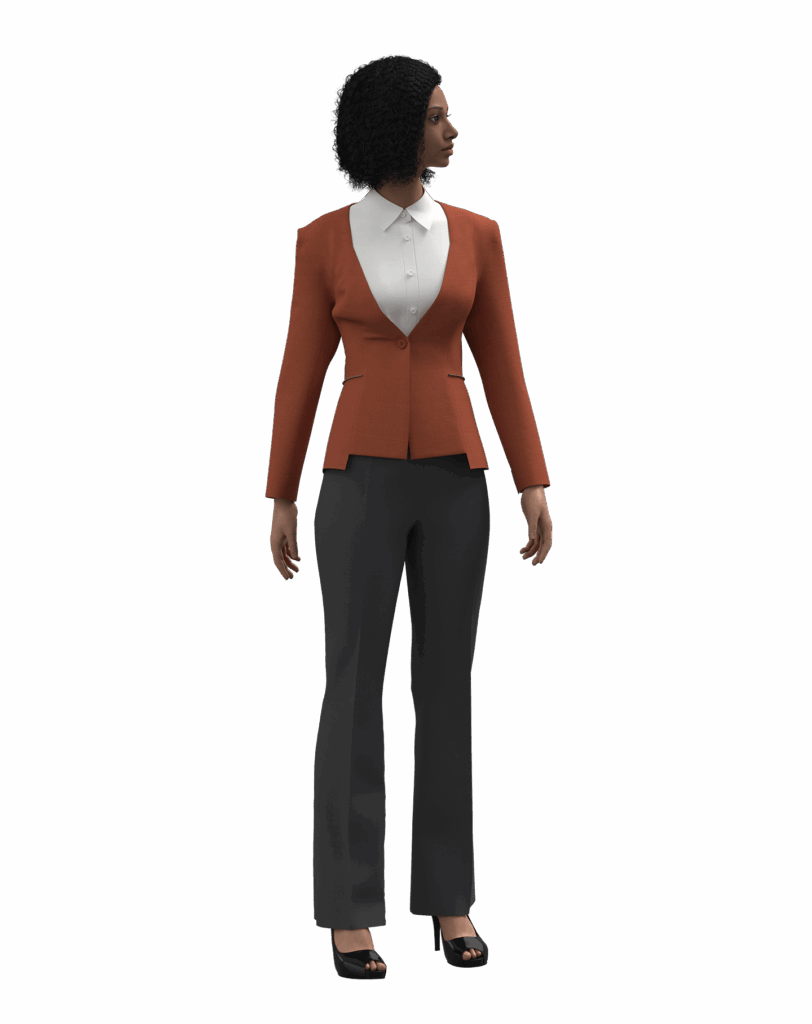

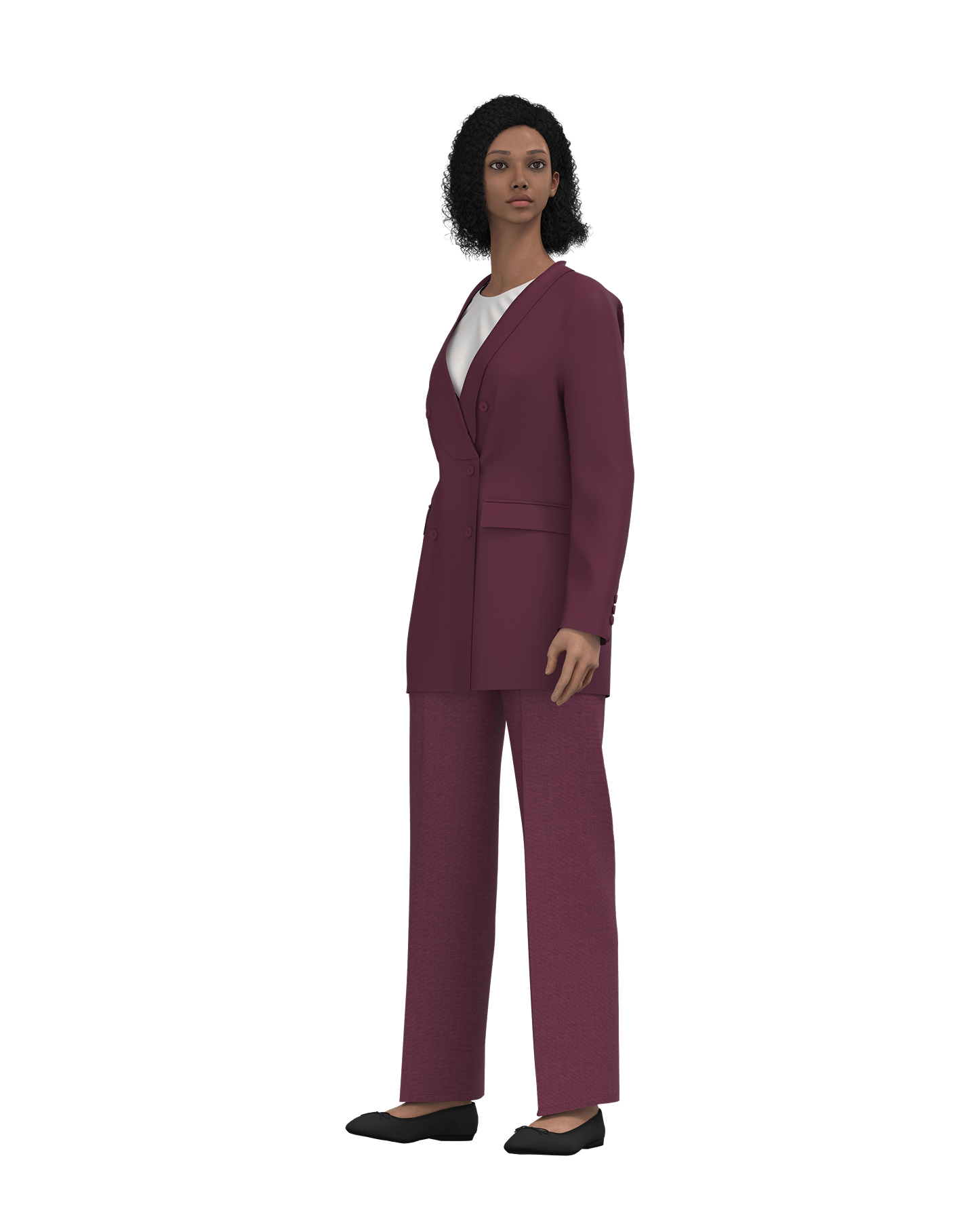

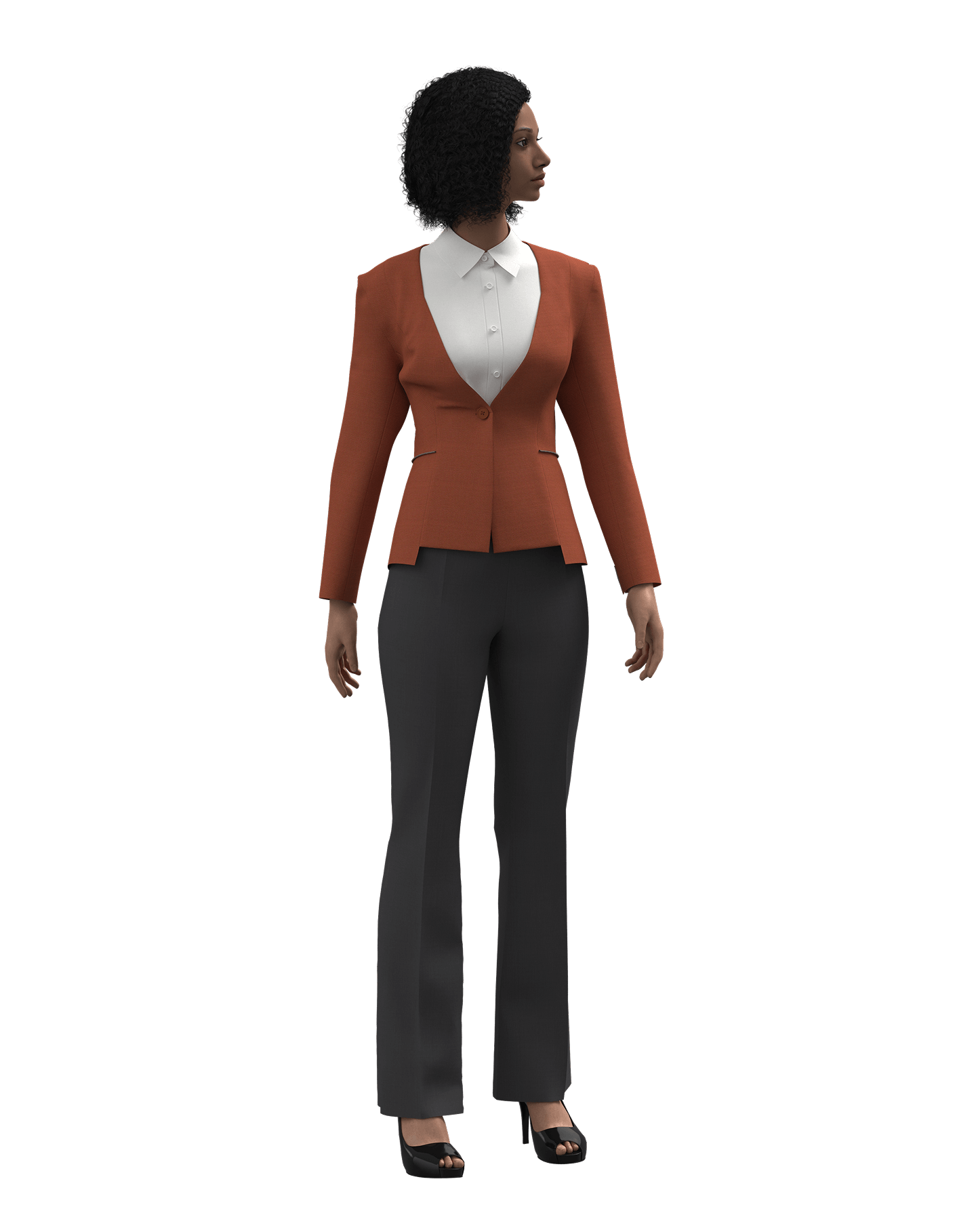

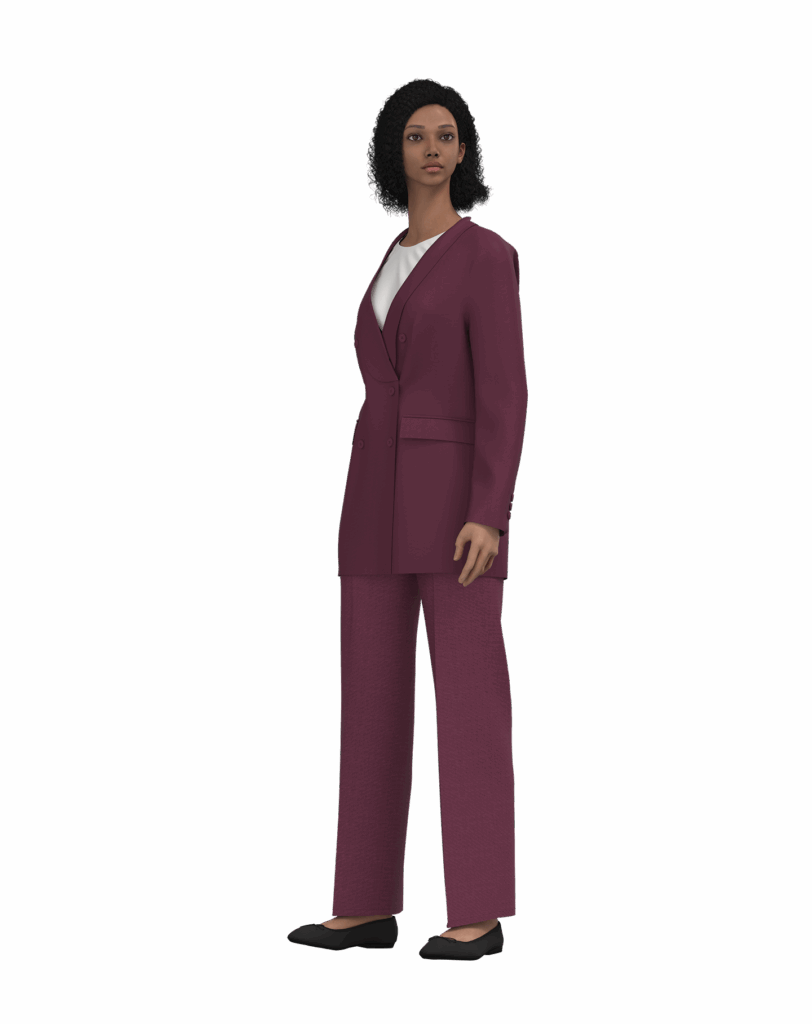

Charlotte Stiffell is a London-based fashion studio specialising in premium corporate workwear and tailored clothing. Their team oversees the complete creative and technical development process, supporting clients across a varied and evolving range of suiting and uniform projects.

Before the training began, the team faced a number of challenges:

The goal was to build an in-house 3D workflow that aligned with their premium tailoring standards and supported both design and technical development.

I created a bespoke 8-week programme delivered through a mix of remote and on-site sessions, tailored specifically to their niche in suiting and corporate uniforms.

Each session followed my usual structure: Live demonstration → guided follow-along → practice → feedback.

To support their learning, I also provided:

The curriculum was designed around their existing product blocks, working with both their historic models and patterns supplied via DXF. Because they have an in-house pattern cutter, the focus remained on workflow, visual accuracy, fit, and presentation, the areas that would have the biggest impact on their business.

The sessions explored a comprehensive mix of creative and technical workflows in CLO3D, all tailored specifically to the demands of suiting and corporate uniform design. We covered:

Every topic was approached through the lens of tailoring, ensuring the tools aligned with their product range and internal workflow.

The training has already begun to influence their internal processes:

Looking ahead, the long-term impact has the potential to support:

To continue building on the foundations from the training, we discussed additional ways CLO3D could support their day-to-day workflow:

These steps will help the team embed CLO3D more fully into their design and development process over time.

“Laura is incredibly friendly, helpful and knowledgeable regarding CLO3D and is eager to provide help in any way she can. We had a lovely time during the sessions and found them valuable in building upon our current understanding of the software, as well as exploring more in-depth topics. Her guidance has benefitted our workflow and overall business greatly. Would highly recommend!”

This feedback reflects the progression I saw in both team members throughout the training. Their openness to learning and willingness to explore new workflows played a significant role in the results they achieved.

This project was a real pleasure to lead. Tailoring is one of the most rewarding categories to teach in 3D because of the attention to detail, precision and craftsmanship involved. The team were enthusiastic, inquisitive and eager to build a workflow that genuinely supports their business.

Watching their confidence grow week by week, from rebuilding the fundamentals to producing polished tailored garments highlighted just how valuable the right training can be. CLO3D is going to play a key role in how they continue to communicate design, streamline development and offer a more efficient service to their clients.

I offer bespoke online and hybrid programmes tailored to your product category, team size and workflow.

If you’d like to explore what this could look like for your business, you’re welcome to get in touch.