I help brands bring their collections to life through efficient, flexible 3D product development workflows. From concept to production handover, I support every stage with industry-relevant tools and insight.

Bring your ideas to life faster, smarter, and more sustainably with 3D product development services designed to support you from first concept to final production handover.

In today’s fast-paced fashion landscape, brands need more than just great designs – they need agile, future-proofed workflows. With over 20 years of hands-on experience in design, product development, and sourcing, I guide brands through every stage of the process, from concept sketching and digital prototyping to technical development and production handover.

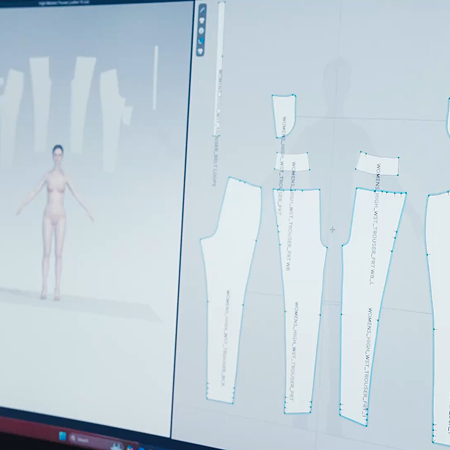

Through tools like CLO3D and a deep understanding of the full product lifecycle, I help brands streamline their workflows, validate designs faster, and reduce reliance on physical sampling. Whether you need support building your first 3D collection, developing digital prototypes for production, or sourcing solutions to bring a concept to life, I create tailored strategies that move you from concept to production with confidence.

Bring your products to life with 3D before a single sample is made. Cut down on physical prototyping, align teams faster, and move from concept to market with confidence.